Metal fabrication is a vital process transforming raw materials into functional and aesthetically pleasing elements for modern offices, including structural support beams, handrails, decorative paneling, and custom furniture. The meticulous process involves interpreting client visions into technical drawings, selecting suitable materials, and using advanced machinery like laser cutting and welding to meet both aesthetic and functional needs. Stainless steel and aluminum offer durability, strength, and versatility, enabling creative design elements that evoke a modern industrial atmosphere while providing long-lasting support for heavy equipment and cost-effective low maintenance. Choosing a reliable metal fabrication partner with expertise in custom work, complex designs, industry standards, advanced equipment, and quality materials ensures successful office projects tailored to specific needs.

“Discover the transformative power of comprehensive metal fabrication for commercial projects, especially in office environments. This article delves into the intricate process, from conceptualization to realization, highlighting its diverse applications and benefits. Learn how custom metalwork enhances aesthetics and functionality in modern offices. Furthermore, explore the importance of selecting a trusted partner for your metal fabrication needs, ensuring exceptional quality and timely delivery. Elevate your space with the art of metal fabrication.”

- Understanding Metal Fabrication for Commercial Spaces

- The Process: From Concept to Completion

- Benefits and Applications in Office Environments

- Choosing the Right Fabrication Partner for Your Project

Understanding Metal Fabrication for Commercial Spaces

Metal fabrication is a critical process in the construction and design of commercial spaces, from offices to retail stores. It involves the creation and customization of metal components to meet specific architectural requirements. This art transforms raw materials into intricate structures, ensuring durability and aesthetics that define modern commercial landscapes.

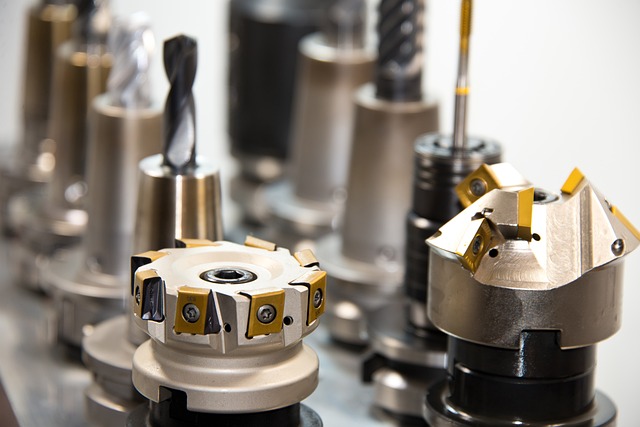

In the context of office spaces, metal fabrication plays a pivotal role in creating functional and visually appealing environments. Fabricated metal elements can be found in everything from structural support beams and handrails to decorative paneling and custom furniture. By employing advanced techniques like laser cutting, welding, and bending, fabricators can produce precise, complex designs that enhance the overall ambiance and functionality of an office while adhering to safety standards and structural integrity requirements.

The Process: From Concept to Completion

The journey of creating custom metal fabrications for commercial projects, like those required for modern offices, is a meticulous process that demands precision and creativity. It begins with understanding the client’s vision, translating their concepts into technical drawings, and selecting the appropriate materials—all while adhering to safety standards. This initial phase sets the foundation for the entire project.

Once the design is finalized, the metal fabrication process kicks into gear. Skilled artisans use advanced machinery and techniques to cut, bend, and shape metal sheets according to the precise specifications. From laser cutting for intricate details to welding for structural integrity, each step ensures the final product meets both aesthetic and functional requirements. Quality control checks are implemented at every stage, guaranteeing that the metal fabrication for offices is of the highest standard.

Benefits and Applications in Office Environments

Metal fabrication, with its versatility and durability, offers a plethora of benefits for commercial projects, especially in office environments. The use of metal in office spaces can transform interior design while providing robust solutions for structural elements. For instance, metal fabrications like stainless steel or aluminium can be creatively incorporated into partitions, desks, and even aesthetic ceiling designs, creating a modern and industrial vibe that enhances productivity and employee satisfaction.

In addition to aesthetics, these materials offer superior strength and longevity, making them ideal for heavy-duty office equipment support. Customizable and adaptable, metal fabrication allows for the creation of unique, space-saving storage solutions and modular workstations, catering to diverse office layouts and workflow requirements. Furthermore, its resistance to wear and tear ensures a low maintenance environment, contributing to cost savings in the long run.

Choosing the Right Fabrication Partner for Your Project

Selecting a reliable and experienced metal fabrication partner is paramount for successful commercial projects, especially when it comes to metal fabrication for offices or any other purpose. This decision can significantly impact project timelines, quality, and overall cost. It’s essential to consider their expertise in custom metalwork, ability to handle complex designs, and adherence to industry standards.

When evaluating potential partners, look for a team with a proven track record in delivering high-quality metal fabrication services on time. They should possess the necessary equipment and skills to transform your design into reality, whether it’s intricate architectural elements or functional office fittings. Additionally, their commitment to using quality materials ensures durability and longevity in any commercial setting.

Metal fabrication is a powerful tool for transforming commercial spaces, offering both aesthetic appeal and functional benefits. As this article has explored, understanding the process from concept to completion is key to achieving exceptional results. From enhancing office aesthetics with custom features to optimizing space with innovative designs, metal fabrication for offices provides endless possibilities. When choosing a partner, look for expertise, quality craftsmanship, and a commitment to meeting your unique project needs, ensuring a successful transformation that stands the test of time.