Commercial metal fabrication is a dynamic industry that transforms raw metals into critical components for diverse sectors, from automotive and aerospace to electronics and construction. This process leverages advanced machinery and expert skills to deliver high-quality, precise parts, offering cost savings, enhanced performance, and sustainability through optimized resource use. Precision metalwork, a specialized facet, excels at creating intricate pieces with unparalleled accuracy, catering to industries like automotive manufacturing and medical device production. Future trends include increased automation for speed and precision, as well as sustainable practices to reduce environmental impact, ensuring commercial metal fabrication remains a key driver of economic growth and innovation.

Precision metalwork is a cornerstone of modern commerce, enabling the creation of intricate components vital to diverse industries. From medical devices to aerospace, commercial applications demand precision, reliability, and consistency in metal fabrication. This article delves into the intricacies of commercial metal fabrication, exploring its role, the meticulous process involved, benefits, challenges, and future trends shaping this dynamic field. Understand the significance of precision metalwork in driving innovation across various sectors.

- Understanding Commercial Metal Fabrication: Its Role and Importance

- The Process of Precision Metalwork for Commercial Applications

- Benefits and Challenges in the Industry

- Future Trends Shaping Commercial Metal Fabrication

Understanding Commercial Metal Fabrication: Its Role and Importance

Commercial metal fabrication plays a pivotal role in shaping modern industries, enabling the creation of intricate components and structures that drive economic growth. This specialized process involves transforming raw metals into precise, functional forms through various techniques such as cutting, bending, forming, and joining. Its significance is profound, serving as a backbone for diverse sectors including automotive, aerospace, construction, and electronics.

Precision metalwork ensures the production of high-quality, reliable parts that meet stringent industry standards. By leveraging advanced machinery and expert craftsmanship, commercial metal fabrication facilitates the development of lightweight materials, enhanced performance, and improved efficiency across applications. This not only reduces costs but also contributes to sustainability by optimizing resource utilization and minimizing waste.

The Process of Precision Metalwork for Commercial Applications

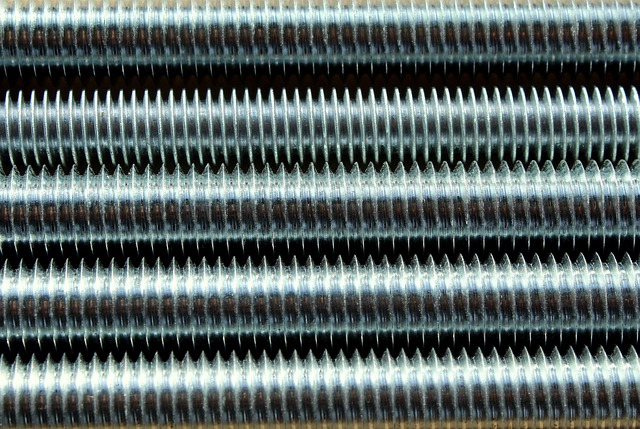

Precision metalwork is a specialized process that plays a vital role in various commercial applications, offering unparalleled accuracy and quality. It involves the art of shaping and forming metals to create intricate parts and components with strict tolerances. This meticulous technique is crucial for industries requiring high-performance, reliable hardware.

The process begins with material selection, choosing the right alloy for the specific application. Skilled artisans then employ advanced machinery, including lathes, mills, and precision cutting tools, to transform raw metal into desired shapes. Each step is meticulously controlled, ensuring dimensional accuracy. Finishing techniques, such as polishing or coating, enhance aesthetics and corrosion resistance, making the final product suitable for diverse commercial settings, from automotive manufacturing to medical device production.

Benefits and Challenges in the Industry

Precision metalwork is a specialized field within the broader realm of commercial metal fabrication, offering numerous benefits to various industries. Its precision and attention to detail enable the creation of intricate components crucial for advanced machinery, medical devices, aerospace parts, and more. The industry’s versatility allows it to cater to diverse client needs, ensuring complex designs are transformed into reality with high accuracy and repeatability.

Despite its advantages, precision metalwork faces challenges. These include managing tight tolerances, especially in large-scale production runs, while maintaining consistent quality. Material properties and their behavior during processing can vary, posing difficulties in achieving the desired specifications. Additionally, staying up-to-date with rapid technological advancements is essential to provide innovative solutions and meet modern industry standards for commercial metal fabrication.

Future Trends Shaping Commercial Metal Fabrication

The future of commercial metal fabrication is being shaped by a range of innovative technologies and shifting market demands. One prominent trend is the increasing adoption of advanced automation and robotics, which promise to enhance precision, speed, and efficiency in metalworking processes. This shift towards automation aims to meet the growing need for complex, high-precision components across various industries.

Additionally, sustainable practices are at the forefront, driving developments in green metal fabrication methods. As environmental concerns continue to mount, commercial metal fabricators are exploring eco-friendly alternatives, such as recycled materials and energy-efficient production techniques. These future trends not only reflect a changing ecological consciousness but also a desire to remain competitive in an increasingly regulated market, ensuring that the commercial metal fabrication industry remains dynamic and responsive to global demands.

Precision metalwork is a cornerstone of modern commercial applications, enabling advancements across industries. As technology evolves, the future of commercial metal fabrication looks promising with emerging trends such as automation and sustainable materials. By understanding the benefits and challenges within this field, businesses can leverage precision metalwork to drive innovation, enhance product quality, and meet growing market demands. Commercial metal fabrication continues to be a dynamic sector, offering endless possibilities for growth and transformation.